In the fast-paced world of manufacturing, precision and efficiency are paramount. CNC (Computer Numerical Control) lathes have revolutionized the way parts are processed, enabling manufacturers to create highly accurate, complex components with minimal human intervention. If you’re looking to enhance your manufacturing capabilities, understanding what parts a CNC lathe is suitable for processing is essential. This article will guide you through the types of parts that can be processed using CNC lathes and why investing in a high-quality CNC lathe, like the HIRUNG EL Series, can help you achieve superior results.

Understanding CNC Lathes

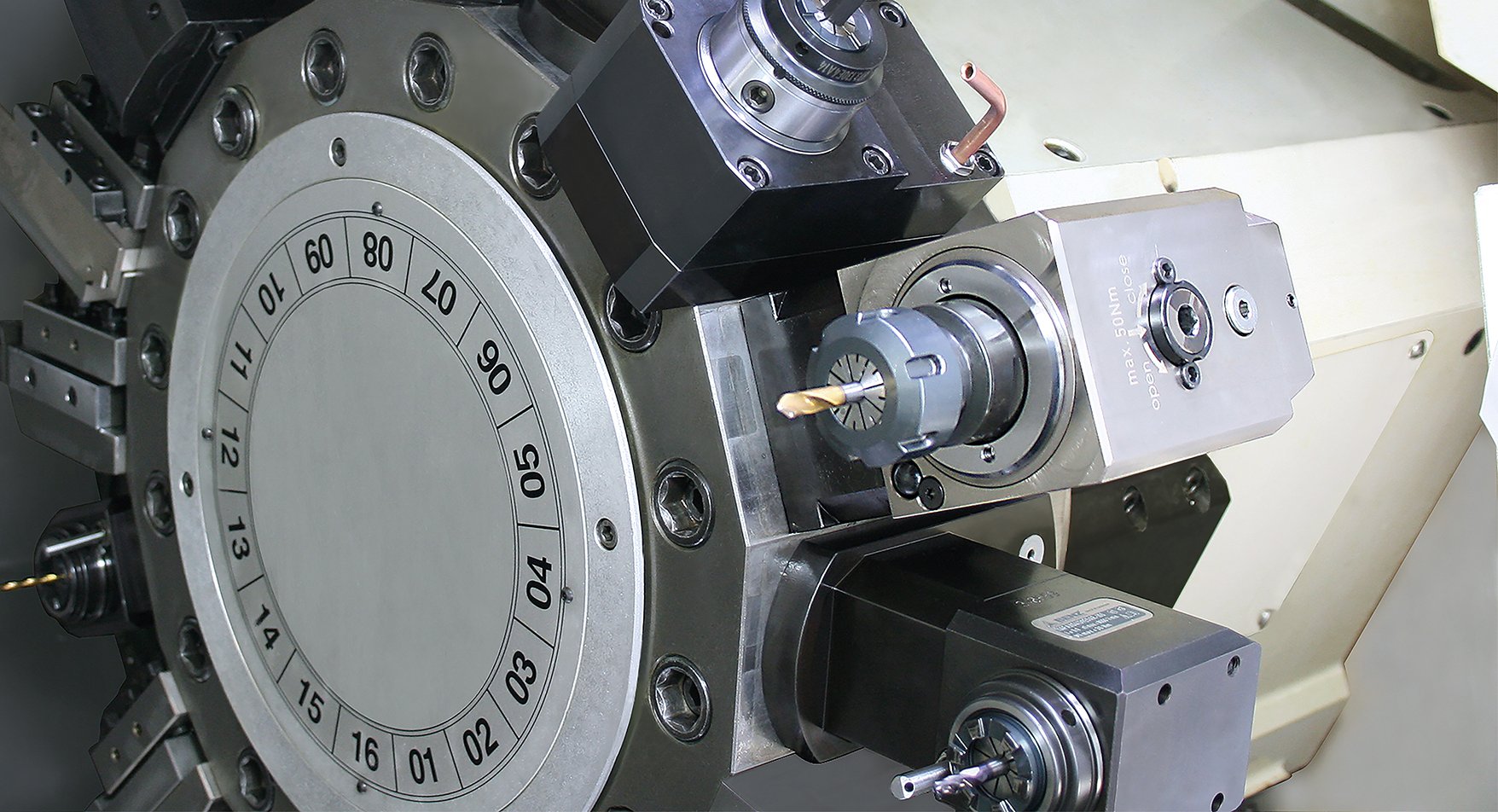

A CNC lathe is a machine tool that uses computerized controls to automatically perform cutting operations on a rotating workpiece. Unlike traditional lathes, which require manual adjustments, CNC lathes offer the precision and repeatability needed for modern manufacturing. The machine uses programmed commands to control the movements of tools, allowing for more complex and intricate designs that would be difficult or time-consuming to achieve by hand.

The versatility of CNC lathes means they are suitable for a wide range of industries. Whether you’re producing small parts for electronics or large components for the aerospace industry, CNC lathes are integral to meeting the demands of today’s high-precision manufacturing.

Types of Parts CNC Lathes Are Suitable for Processing

1. Metal Parts

CNC lathes are ideal for processing a variety of metal components. These machines can work with materials like steel, aluminum, brass, and titanium, allowing manufacturers to produce parts with tight tolerances. Examples include shafts, gears, bushings, and bearings—critical components in industries like automotive, machinery, and construction.

With their ability to maintain consistent cutting speeds and precision, CNC lathes ensure that each part is produced with minimal variation, making them an excellent choice for mass production of metal parts.

2. Automotive Parts

The automotive industry requires high-quality, durable components to ensure the functionality and safety of vehicles. CNC lathes are widely used to produce parts like crankshafts, camshafts, pistons, and engine blocks. These components need to meet stringent quality standards, and CNC lathes are up to the task, delivering the precision and reliability necessary for critical automotive applications.

By using CNC technology, manufacturers can efficiently produce automotive parts with intricate shapes and features, reducing the risk of defects and ensuring longer-lasting performance.

3. Aerospace Parts

In the aerospace industry, safety and precision are non-negotiable. CNC lathes play a crucial role in the production of parts for aircraft, such as turbine blades, housings, brackets, and fasteners. These components often require complex geometries, and the high level of accuracy that CNC lathes provide ensures that each part meets the strict specifications needed for aerospace applications.

CNC lathes are also capable of working with specialized materials used in aerospace manufacturing, such as high-strength alloys and composites, further enhancing their versatility and value to the industry.

4. Medical Components

The medical industry relies on precision parts that meet stringent regulatory requirements. CNC lathes are ideal for processing medical components like implants, surgical instruments, and diagnostic equipment housings. These parts often require tight tolerances, smooth finishes, and biocompatibility, all of which can be achieved with CNC machining.

By using CNC lathes, manufacturers can produce medical parts in large quantities while ensuring the consistency and accuracy needed for safe, functional products.

5. Electronic Parts

CNC lathes are essential for producing small, detailed parts used in the electronics industry, such as connectors, housings, covers, and mounting brackets. These parts require precise machining to ensure proper fit and function within electronic devices. CNC lathes are capable of handling delicate materials and creating fine features that are crucial for high-performance electronics.

With the growing demand for miniaturization in electronic devices, CNC lathes are key to producing smaller, more intricate parts at scale without compromising quality.

6. Industrial Machinery Parts

CNC lathes are extensively used to manufacture parts for industrial machinery, including pumps, valves, gears, and compressors. These components are often subjected to high stress and wear, so they need to be manufactured with exceptional durability and precision. CNC lathes provide the repeatability and consistency required to produce these parts with tight tolerances, ensuring reliable performance in heavy machinery.

7. Custom and Prototype Parts

One of the most significant advantages of CNC lathes is their ability to create custom parts and prototypes. Whether you’re working with unique designs or experimenting with new ideas, CNC lathes can bring your vision to life with a high degree of accuracy. The flexibility of CNC programming allows for quick adjustments, making it easier to refine prototypes before moving to mass production.

This versatility is particularly valuable in industries like aerospace, automotive, and consumer electronics, where innovation and customization are essential.

Advantages of Using CNC Lathes for Processing Parts

Precision and Accuracy

CNC lathes offer exceptional precision, which is essential for producing high-quality parts that meet strict tolerances. This precision ensures that parts fit together perfectly, reducing the need for manual adjustments and rework.

Complex Geometries

CNC lathes are capable of producing complex shapes and features that would be difficult or impossible to achieve with traditional machining methods. Whether you need intricate threads, contours, or patterns, CNC lathes can handle it with ease.

Consistency and Repeatability

CNC lathes ensure that every part produced is identical, which is crucial for mass production. This consistency eliminates human error, resulting in higher-quality products and less scrap.

Material Versatility

CNC lathes can work with a wide range of materials, from metals to plastics and composites. This versatility makes them suitable for a broad spectrum of industries, from aerospace to consumer goods.

Cost Efficiency

While CNC machines can be expensive upfront, they offer significant cost savings in the long run. By increasing production efficiency, reducing waste, and lowering labor costs, CNC lathes help businesses maximize their return on investment.

Why Choose the HIRUNG EL Series CNC Lathe?

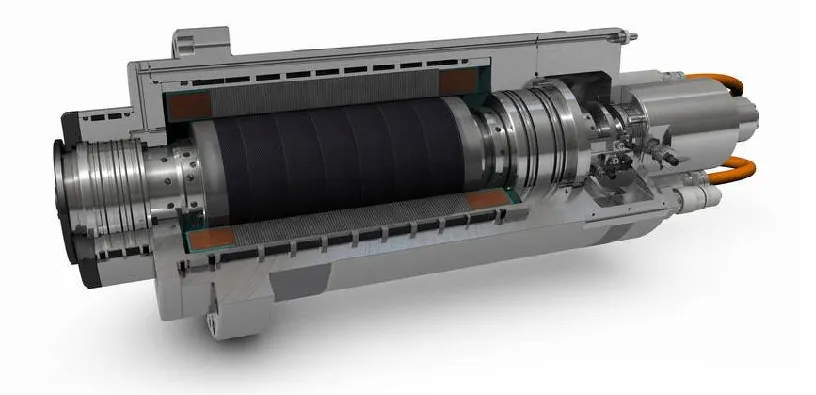

At HIRUNG, we understand the importance of precision and reliability in machining. Our EL Series CNC lathe is the third-generation product from our company, built on over 20 years of expertise in CNC machine manufacturing. The EL Series represents the culmination of our commitment to continuous improvement, ensuring that every machine provides exceptional stability, accuracy, and efficiency.

With the EL Series, you can expect:

- Superior Quality: We use high-standard manufacturing processes to ensure the durability and precision of every machine.

- Enhanced User Experience: The EL Series is designed with the user in mind, offering an intuitive interface and easy maintenance, ensuring a seamless experience from setup to operation.

- Global Trust: HIRUNG’s CNC machines are trusted by manufacturers in 33 countries and regions worldwide. Our products are known for their superior quality and precision, which are unmatched by other Chinese brands.

If you’re looking for a CNC lathe that guarantees precision, reliability, and outstanding performance, the HIRUNG EL Series is the perfect choice.

Conclusion

CNC lathes have become an indispensable tool for manufacturers looking to produce precise, high-quality parts. Whether you’re in the automotive, aerospace, medical, or electronics industry, CNC lathes are capable of processing a wide range of parts with unmatched accuracy and efficiency. By investing in a high-quality CNC lathe, like the HIRUNG EL Series, you can ensure that your manufacturing processes meet the demands of today’s competitive market while achieving superior results.