Introduction

In the world of manufacturing, lathes play a pivotal role in shaping materials into precise components. As technology has evolved, so too have the tools we use, leading to a significant shift from traditional manual lathes to modern CNC (Computer Numerical Control) lathes. This article aims to clarify the key differences between these two types of lathes, helping you make an informed decision based on your specific manufacturing needs.

1. Definition and Functionality

Manual Lathes

Manual lathes are traditional machines operated by skilled technicians who control the cutting tools directly. Operators adjust settings and manipulate the workpiece by hand, relying on their experience and skill to achieve desired results. This hands-on approach allows for a tactile connection with the material but can lead to variations in precision.

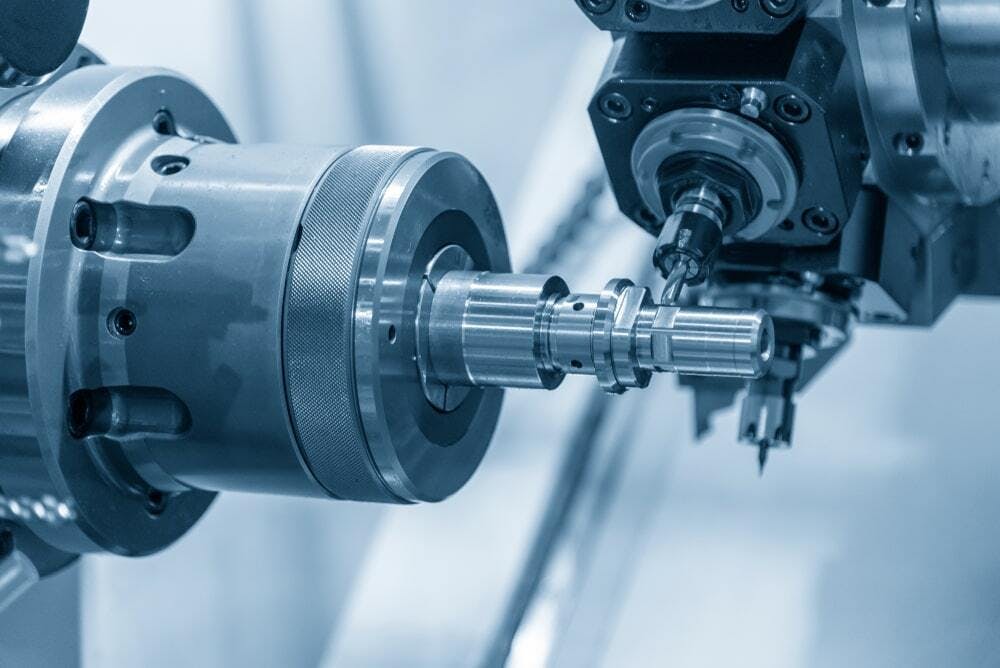

CNC Lathes

CNC lathes, on the other hand, automate the machining process through computer programming. Operators input design specifications into a computer, which then controls the lathe’s movements with high precision. This automation significantly reduces human error and enhances production speed.

2. Key Differences

| Feature | Manual Lathes | CNC Lathes |

| Control Method | Manual operation | Computer-controlled |

| Precision | Less precise, dependent on operator | High precision with minimal errors |

| Production Speed | Slower due to manual processes | Faster due to automation |

| Setup Time | Longer setup for each job | Quick setup with programmable settings |

| Skill Level Required | Requires skilled operators | Can be operated with basic training |

3. Advantages and Disadvantages

Manual Lathes

- Advantages:

- Lower Initial Cost: Manual lathes typically require a smaller investment upfront compared to CNC machines.

- Greater Tactile Feedback: Operators can feel and adjust their cuts in real-time, allowing for creative adjustments.

- Disadvantages:

- Slower Production: The manual nature of these machines can lead to longer production times.

- Higher Risk of Human Error: Variability in operator skill can lead to inconsistencies in product quality.

CNC Lathes

- Advantages:

- High Efficiency: CNC lathes can produce parts at a much faster rate due to automation.

- Repeatability: Once programmed, CNC machines can produce identical parts consistently, reducing waste.

- Disadvantages:

- Higher Upfront Investment: The initial cost of purchasing CNC machinery can be significant.

- Requires Technical Knowledge: Operators need training to program and troubleshoot CNC machines effectively.

4. Cost Differences Between Manual and CNC Lathes

When considering the cost of lathes, it’s essential to look at both initial and operating costs:

- Initial Costs: CNC lathes are generally much more expensive than manual lathes. The price varies based on machine type, size, capacity, and features. High-precision CNC machines equipped with advanced automation can be particularly costly.

- Operating Costs: While CNC lathes have higher initial costs, they often result in lower operating costs over time due to reduced labor requirements and increased efficiency. Manual lathes typically incur higher labor costs because they require skilled operators for setup and operation.

In summary, while manual lathes may be more affordable initially, CNC lathes offer long-term cost benefits through efficiency and reduced labor needs.

5. How to Choose the Right Lathe for Your Business

Choosing between manual and CNC lathes depends on several factors:

- Production Volume: For high-volume production runs or complex parts requiring tight tolerances, CNC lathes are generally preferred due to their speed and accuracy. Conversely, for small-scale or custom jobs, manual lathes may be more suitable.

- Budget Constraints: If your budget is limited, starting with a manual lathe might be a practical choice. However, consider the long-term costs associated with labor and efficiency when making your decision.

- Skill Level of Operators: If you have skilled machinists available who can operate manual machines effectively, this might influence your choice. On the other hand, if you have less experienced staff or require consistent output, investing in CNC technology could be beneficial.

6. Maintenance Requirements for CNC Lathes

CNC lathes come with specific maintenance needs that differ from manual machines:

- Regular Software Updates: Keeping the machine’s software up-to-date ensures optimal performance and accuracy.

- Routine Mechanical Checks: Regular inspections of mechanical components such as bearings and motors help prevent breakdowns.

- Calibration and Alignment: Periodic calibration is necessary to maintain precision in machining operations.

While maintenance for CNC machines can be more complex due to their automated systems, they often require less frequent service compared to manual machines that endure more wear from operator handling.

Conclusion

Understanding the differences between manual lathes and CNC lathes is crucial for businesses looking to optimize their manufacturing processes. Each type has its unique advantages and disadvantages that cater to different needs within the industry.

At HIRUNG, we offer a range of high-quality CNC machine tools designed for stability and efficiency. With over 1,000 successful international sales since 2015, our machines are proven to minimize downtime and maximize productivity. If you’re considering upgrading your machinery or have any questions about our products, please contact us today!