Milling machines are indispensable tools in the manufacturing sector, designed to cut and shape materials with precision. Understanding how a milling machine works can significantly enhance your machining knowledge and improve your manufacturing processes. This article delves into the intricate workings of milling machines, breaking down each component and step involved in the milling process. By exploring the setup, operation, and key features of these machines, you will gain valuable insights that can optimize your production efficiency and quality.

1. The Basic Setup

Before any milling operation begins, proper setup is critical to ensure accuracy and efficiency. Here’s how it’s done:

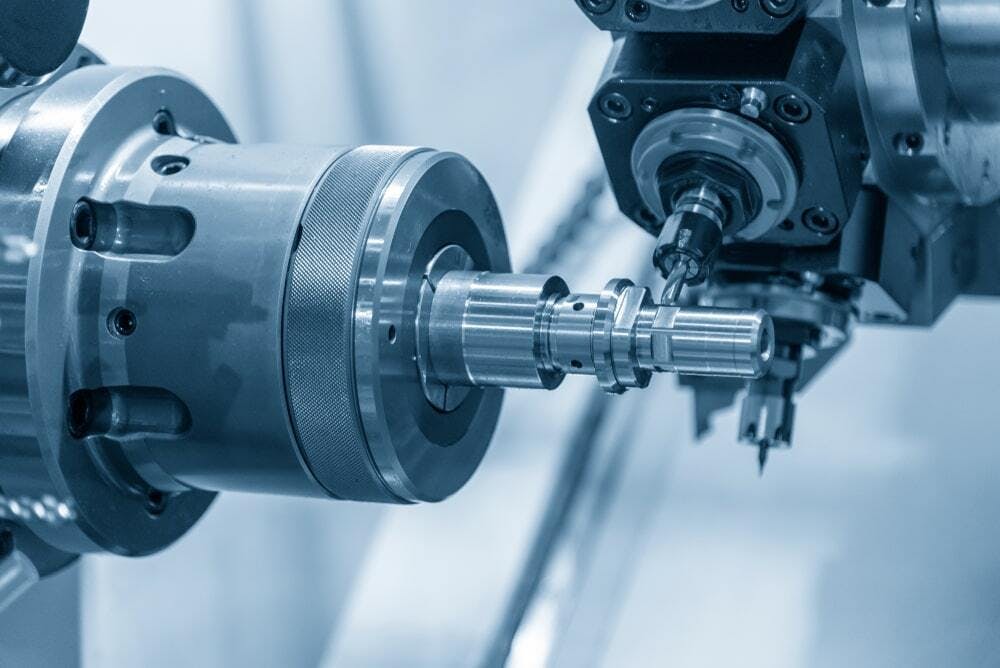

- Cutting Tool Adjustment: First, securely mount the cutting tool onto the arbor, which attaches to the spindle of the milling machine. The spindle is responsible for rotating the cutter at high speeds, essential for effective material removal.

- Knee Adjustment: Next, adjust the knee of the milling machine to set the initial height of the cutter in relation to the workpiece. This adjustment is crucial for ensuring that the cutter engages with the material correctly.

2. Clamping the Workpiece

Once you have set up the cutting tool, secure the workpiece onto the machine’s table. Use clamping screws or vises for this purpose. A stable and secure fixture is vital; any movement during machining can lead to inaccuracies and defects in the final product.

3. Zero Adjustment

Before starting the milling operation, calibrate all control points—such as saddle position and knee position—to zero. This calibration ensures that subsequent movements can be accurately measured, allowing for precise machining of components.

4. The Cutting Tool Activation

With everything in place, activate the spindle to rotate, causing the attached cutting tool to spin at high speeds. This rotary motion allows the cutter’s teeth to engage effectively with the workpiece material.

5. Moving the Workpiece

The actual milling operation commences when you move the workpiece against the rotating cutter. This movement can occur in various directions—longitudinally, vertically, or diagonally—depending on your desired cut and machine configuration. Operators control this movement through adjustments made to different parts of the machine:

- Table Movement: The table can be moved in three directions:

- Vertical Movement: Adjusted by raising or lowering the knee.

- Cross Movement: Achieved by moving the saddle back and forth.

- Longitudinal Movement: Controlled by a hand wheel fitted on the side of the feed screw.

6. Shaping the Workpiece

As you advance the workpiece toward the cutter, its surface gradually takes shape as material is removed by the cutter’s teeth. The milling process can be categorized into several operations:

- Roughing: This initial phase focuses on quickly removing excess material to bring the workpiece closer to its intended shape.

- Semi-finishing: Following roughing, this stage refines the shape more closely to specifications.

- Finishing: In this final phase, very fine cuts are made at a slow feed rate to achieve high precision and an excellent surface finish.

This combination of operations allows for intricate designs and shapes to be machined effectively.

7. Unloading and Inspection

Once machining is complete, remove the finished part from the milling machine. It undergoes inspection for quality control purposes to ensure it meets required specifications. If defects are found, reworking or additional finishing passes may be necessary.

Conclusion

Understanding how a milling machine works is fundamental for anyone involved in manufacturing or machining processes. From initial setup through shaping and inspection, each step plays a vital role in producing high-quality parts.

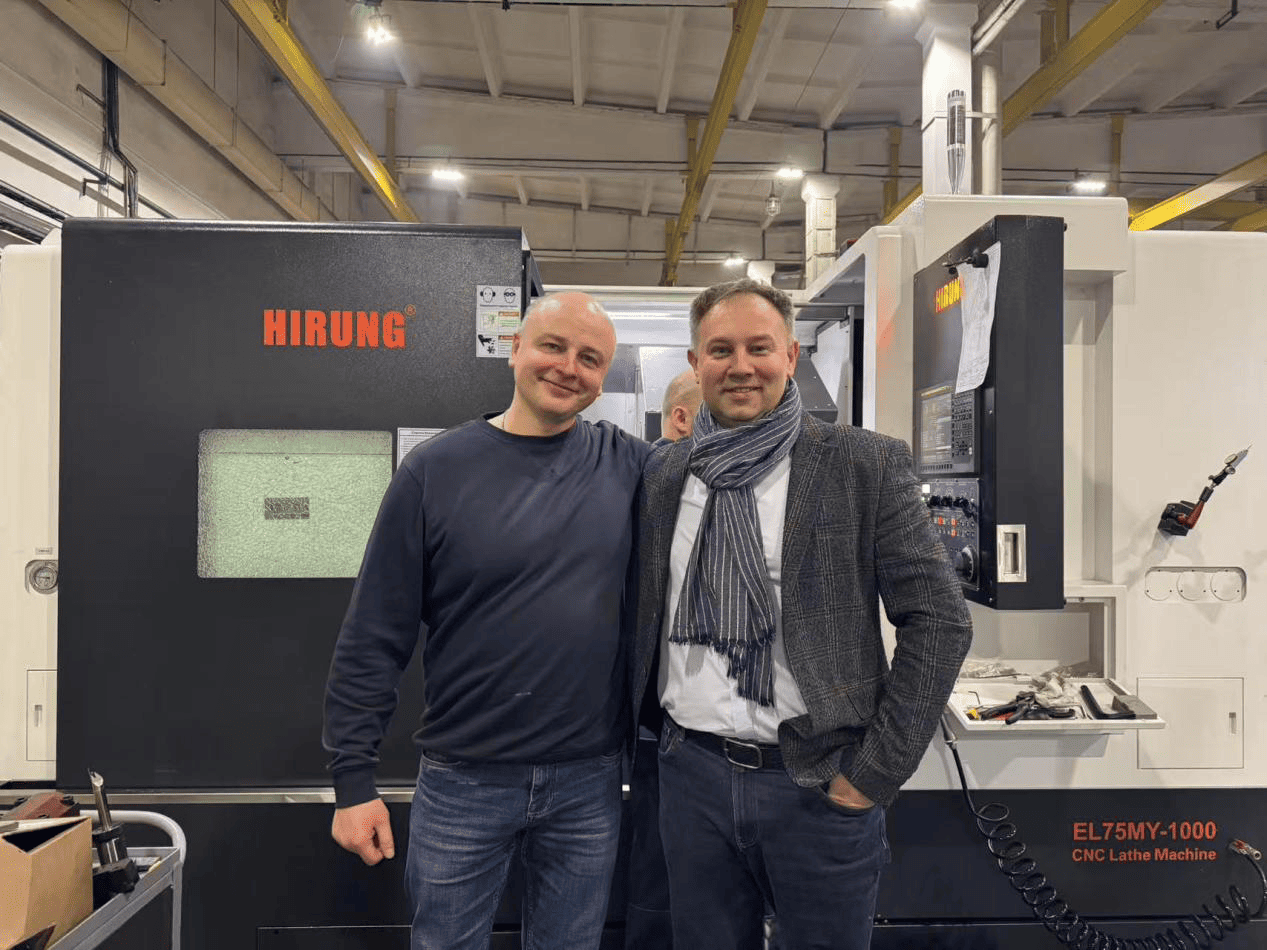

For reliable CNC machine tools that promise stability and efficiency in your operations, consider HIRUNG. Since our international sales began in 2015, we have exported over 1,000 machines with minimal failure notifications—demonstrating our commitment to quality and after-sales service. If you encounter any issues with your HIRUNG machines, we guarantee prompt solutions anytime! Contact us today for more information on our products and services.