The CNC vertical machining centers market has experienced significant growth in recent years, driven by advancements in automation and the increasing demand for precision manufacturing across various industries. As of 2024, the market size was estimated at USD 9.71 billion, with projections indicating a rise to USD 16.37 billion by 2034, reflecting a compound annual growth rate (CAGR) of approximately 5.36% during the forecast period.

Understanding CNC Vertical Machining Centers

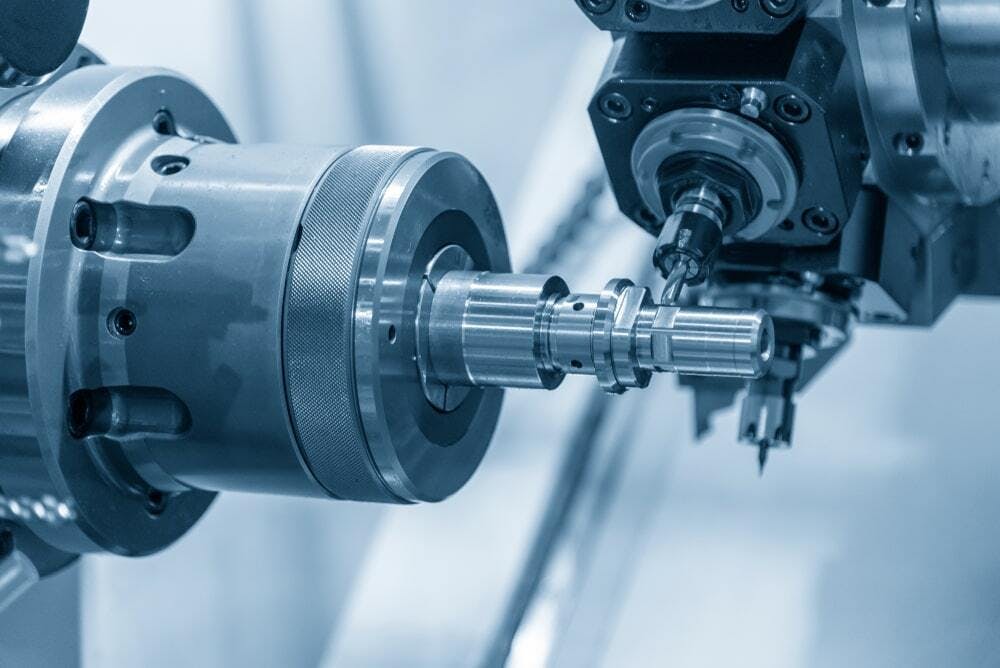

CNC vertical machining centers are automated machines controlled by computer programs, capable of performing multiple machining operations such as milling, drilling, tapping, and boring with high precision. They are essential in industries requiring complex and customized parts, offering advantages like enhanced efficiency, accuracy, and the ability to handle intricate designs.

Market Drivers

Advancements in Automation

The integration of advanced control systems, including adaptive control and computer-aided manufacturing (CAM), has significantly enhanced the efficiency and accuracy of vertical machining centers. These technologies enable manufacturers to optimize production processes, catering to the growing need for complex and customized parts.

Demand for Precision Manufacturing

Industries such as aerospace, automotive, and medical devices require components with high precision and tight tolerances. CNC vertical machining centers are indispensable in producing these parts, driving their adoption across these sectors.

Adoption of Industry 4.0

The shift towards Industry 4.0 has led to increased demand for smart manufacturing solutions. Vertical machining centers equipped with Internet of Things (IoT) capabilities and real-time monitoring features are becoming increasingly popular, allowing for predictive maintenance and enhanced operational efficiency.

Market Segmentation

The CNC vertical machining centers market can be segmented based on spindle speed and axis configuration:

Spindle Speed

- Low Speed (Below 4000 RPM): Suitable for heavy-duty machining operations.

- Medium Speed (4000-8000 RPM): Dominant in the market, accounting for approximately 45% of the share in 2023.

- High Speed (Above 8000 RPM): Ideal for precision machining of complex parts.

Axis Configuration

- Less than 5-Axis: Commonly used for simpler machining tasks.

- 5-Axis or More: Increasingly adopted for complex machining operations, offering greater flexibility and precision.

Regional Insights

North America

The North American market is characterized by a high demand for precision manufacturing, particularly in the aerospace and automotive sectors. The adoption of advanced manufacturing technologies is driving the growth of CNC vertical machining centers in this region.

Europe

Europe’s market growth is fueled by the automotive and aerospace industries, with countries like Germany and Italy leading in manufacturing capabilities. The emphasis on high-quality production standards contributes to the demand for advanced machining centers.

Asia-Pacific

The Asia-Pacific region is experiencing rapid industrialization, with countries like China and India investing heavily in manufacturing infrastructure. The growing automotive and electronics sectors are significant contributors to the demand for CNC vertical machining centers.

Challenges

Despite the positive growth trajectory, the market faces several challenges:

- High Initial Investment: The cost of acquiring advanced CNC vertical machining centers can be substantial, posing a barrier for small and medium-sized enterprises.

- Skilled Labor Shortage: Operating and maintaining these sophisticated machines require a skilled workforce, which is in limited supply in certain regions.

- Competition from Horizontal Machining Centers: Horizontal machining centers offer advantages in certain applications, leading to competition in the market.

Future Outlook

The CNC vertical machining centers market is poised for continued growth, driven by technological advancements and increasing demand for precision manufacturing. The integration of artificial intelligence (AI) and machine learning is expected to further enhance the capabilities of these machines, leading to more efficient and flexible manufacturing processes.

Conclusion

The CNC vertical machining centers market is experiencing robust growth, propelled by advancements in automation, the demand for precision manufacturing, and the adoption of Industry 4.0 technologies. As industries continue to evolve, the need for high-quality, efficient, and precise machining solutions will drive the demand for these centers.

At DONGGUAN HIRUNG PRECISION MACHINERY CO., LTD, we are committed to delivering high-end CNC vertical machining centers that meet the evolving needs of the manufacturing industry. Our machines are designed with advanced features to ensure precision, efficiency, and reliability, supporting manufacturers in achieving their production goals.

For more information on our products and how they can enhance your manufacturing processes, please visit our website or contact our sales team.

References:

- Market Research Future. (2025). CNC Vertical Machining Center Market Size, Growth Report 2034.

- Grand View Research. (2023). CNC Machining And Turning Centers Market Report, 2030.

- PR Newswire. (2025). CNC Vertical Machining Centers Market to Grow by USD 1.09 Billion (2025-2029), Driven by Demand for CNC Tools and AI-Powered Market Evolution.

- Allied Market Research. (2023). Vertical Machining Center Market Analysis & Industry Insights by 2030.

- Technavio. (2025). CNC Vertical Machining Centers Market Analysis – US, China, Japan, Germany, Italy – Size and Forecast 2024-2028.