Imagine turning a piece of wood or metal into a custom creation with the precision of a professional workshop. CNC (Computer Numerical Control) machines make this possible, and they’re now within reach for hobbyists, students, and small business owners. But as a beginner, how do you choose the best CNC machine for beginners to start your machining journey? This guide, crafted with insights from HIRUNG’s expertise in precision CNC technology, walks you through everything you need to know—from understanding CNC basics to selecting an affordable, easy-to-use machine. Whether you’re carving signs or prototyping products, let’s help you find the perfect CNC to spark your creativity.

What Are CNC Machines?

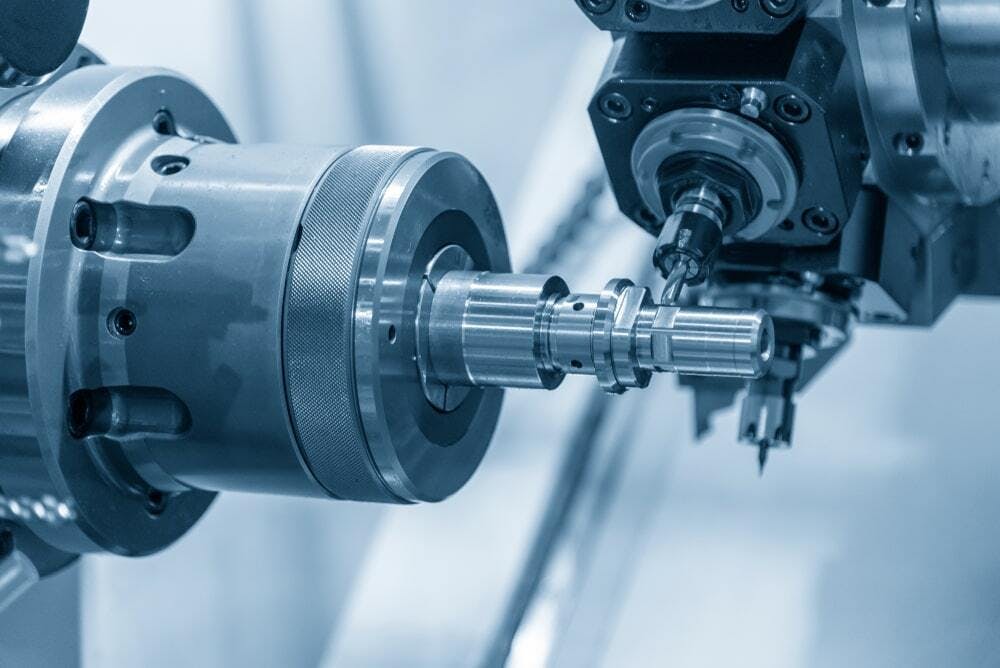

CNC machines are automated tools that use computer programs to control cutting, drilling, carving, or engraving on materials like wood, plastic, or soft metals. You design a project on software, upload it to the machine, and it executes your design with remarkable accuracy. Think of it as a digital craftsman that brings your ideas to life.

Types of CNC Machines

- CNC Routers: Versatile for wood, plastics, and soft metals like aluminum. They’re the top choice for beginners due to ease of use.

- CNC Mills: Built for harder materials like steel, but often complex for new users.

- CNC Lathes: Designed for round parts, such as spindles or shafts, through turning.

- CNC Laser Cutters: Use lasers for precise cuts or engravings, ideal for detailed work.

For beginners, CNC routers are the most approachable, offering flexibility for projects like custom decor, signage, or small prototypes.

Why Beginners Love CNC Machines

- Creative Projects: Make personalized gifts, furniture, or jewelry.

- Business Potential: Prototype products or start a side hustle.

- Learning Opportunity: Develop skills in design, programming, and machining.

How to Choose a CNC Machine as a Beginner

Selecting your first CNC machine doesn’t have to be daunting. Focus on these key factors to find an entry-level CNC machine that fits your needs and budget:

1. Budget

- Under $500: Basic machines for small projects like engraving or cutting thin wood.

- $500–$2,000: More reliable options with larger work areas and better features.

- Over $2,000: Advanced machines for those planning to scale up quickly.

Beginners should prioritize affordability to learn the basics without a big investment. As your skills grow, you can upgrade to high-precision machines like those from HIRUNG, which offer superior accuracy at competitive prices.

2. Machine Size and Work Area

- Desktop Models: Compact, with work areas like 12” x 12” (300 x 300 mm), perfect for small spaces.

- Larger Models: Need a workshop but offer work areas up to 24” x 24” for bigger projects.

Ensure the machine’s work area matches your project sizes, such as cutting small signs or larger furniture pieces.

3. Ease of Use

- Look for machines with simple controls, clear instructions, and beginner-friendly software.

- Features like pre-assembled frames or guided setup tutorials can make your first experience smooth.

4. Software Compatibility

- Choose machines that support free or low-cost software like Easel (web-based, beginner-focused) or Fusion 360 (free for hobbyists, ideal for 3D designs).

- Check if the machine includes software tutorials or templates to ease the learning curve.

5. Support and Resources

- A robust support system is vital for beginners. Prioritize machines with access to online tutorials, forums, or responsive customer service.

- Platforms like YouTube and Instructables offer excellent CNC tutorials to supplement your learning.

6. Scalability

- Consider machines that allow upgrades, such as stronger spindles or larger work areas, as your skills improve.

- When you’re ready to step up, HIRUNG’s CNC machines provide unmatched precision and cost-effectiveness, making them ideal for upgrading hobbyists.

Features of Beginner-Friendly CNC Machines

The best CNC machines for hobbyists share common traits that make learning enjoyable and productive. Here’s what to look for:

- Affordable Price: Ideally $2,000 or less to minimize risk while you learn.

- Simple Setup: Pre-assembled or easy-to-build designs that take 1–2 hours to set up.

- Intuitive Software: Compatible with free tools like Easel, with built-in templates for quick starts.

- Compact Design: Desktop-sized for home use, fitting on a workbench or table.

- Versatile Materials: Capable of cutting wood, plastics, and soft metals like aluminum.

- Community Support: Access to forums, tutorials, or guides to troubleshoot and inspire.

These features ensure you can focus on creating rather than wrestling with complex equipment. As you gain experience, you may want to explore advanced options like HIRUNG’s CNC Machines, which deliver industry-leading precision at prices lower than many competitors.

Practical Examples: Matching Machines to Beginner Projects

To help you visualize the right machine, here are three common beginner scenarios and the ideal CNC features for each:

Scenario 1: Woodworking Hobbyist

- Goal: Carve wooden signs or decorative panels for home decor.

- Needs: Compact router, high-speed spindle (10,000–18,000 RPM), simple software.

- Ideal Machine: A desktop CNC router with a 300 x 300 mm work area, priced around $500–$800, compatible with Easel.

- Why It Works: Small size fits home workshops, and high RPM ensures clean cuts in wood.

Scenario 2: Small Business Prototype

- Goal: Create plastic or aluminum prototypes for a product line.

- Needs: Larger work area, durable frame, support for 3D design software.

- Ideal Machine: A mid-size router with a 600 x 600 mm work area, 2–3 kW spindle, priced $1,000–$1,800, compatible with Fusion 360.

- Why It Works: Handles bigger projects and complex designs, with room to grow.

Scenario 3: Student Learning CNC

- Goal: Learn machining for engineering or design courses.

- Needs: Affordable, safe, with ample learning resources.

- Ideal Machine: An entry-level router under $500 with safety features and access to online tutorials.

- Why It Works: Budget-friendly and supported by platforms like YouTube for skill-building.

When these beginners are ready to upgrade, HIRUNG’s CNC machines offer a perfect next step, combining high precision (e.g., tolerances below 0.01 mm) and cost savings compared to other high-end brands.

Upgrading with HIRUNG: Precision and Value for Growing Skills

As your CNC skills improve, you’ll likely outgrow basic machines and crave greater accuracy and efficiency. This is where HIRUNG shines. Our machining centers are designed for users ready to take their craft to the next level, offering:

- Unmatched Precision: Achieve tolerances as tight as 0.005 mm, ideal for intricate parts or professional-grade projects.

- Cost-Effectiveness: Priced up to 30% lower than comparable high-precision brands, delivering exceptional value.

- Robust Features: High-power spindles (up to 15 kW), large work areas, and compatibility with advanced software like Fusion 360.

- Reliable Support: 24/7 customer service, detailed tutorials, and a global community of HIRUNG users.

For example, a hobbyist moving from small signs to furniture production might choose a HIRUNG router with a 1200 x 1200 mm work area and a 5 kW spindle, priced competitively to fit an upgrading budget. Contact HIRUNG at hirung@hirung.com to explore options when you’re ready to upgrade.

Getting Started with Your First CNC Machine

Once you’ve chosen your beginner CNC machine, these tips will help you succeed:

1. Set Up Your Machine

- Follow the manufacturer’s manual for assembly, typically taking 1–2 hours.

- Secure the machine to a stable surface and wear safety gear, such as goggles and ear protection.

- Test the spindle and movement to ensure everything runs smoothly.

2. Learn Design Software

- Start with Easel for its simplicity—free, web-based, and packed with beginner templates.

- Explore Fusion 360 for 3D designs, free for hobbyists and widely used.

- Check YouTube for tutorials or visit Instructables for project ideas and step-by-step guides.

3. Try Your First Project

- Begin with a simple task, like carving a name into wood or cutting a basic shape (e.g., a circle or star).

- Use scrap material to experiment with speed, depth, and tool settings.

- Start with soft materials like plywood or foam to build confidence.

4. Maintain Your Machine

- Clean dust from rails and the work area after each use to prevent wear.

- Lubricate moving parts monthly, following the machine’s maintenance guide.

- Inspect the spindle and tools regularly for signs of wear.

5. Join a Community

- Engage with CNC communities on platforms like Reddit’s r/CNC or Instructables to share projects and get advice.

- Watch YouTube channels dedicated to CNC for tips on everything from software to troubleshooting.

Beginner CNC Machine Features

To help you choose, here’s a comparison of key features for beginner-friendly CNC machines:

| Feature | Typical Beginner CNC |

| Price Range | $300–$2,000 |

| Work Area | 300 x 300 mm to 600 x 600 mm |

| Ease of Use | Simple controls, basic software |

| Software | Easel, Fusion 360 |

| Precision | 0.1–0.5 mm |

| Support | Varies, often limited |

Conclusion

Choosing the best CNC machine for beginners is about finding an affordable, easy-to-use tool that sparks your creativity and grows with your skills. Start with a budget-friendly CNC router that supports simple software and offers community resources, then upgrade to advanced machines as your expertise expands. When you’re ready for the next level, HIRUNG’s CNC solutions—renowned for precision and up to 30% lower costs than competitors—are here to elevate your craft. Begin your CNC journey today with a beginner machine, and explore HIRUNG’s offerings at www.hirung.com when it’s time to upgrade. Let’s turn your ideas into reality!