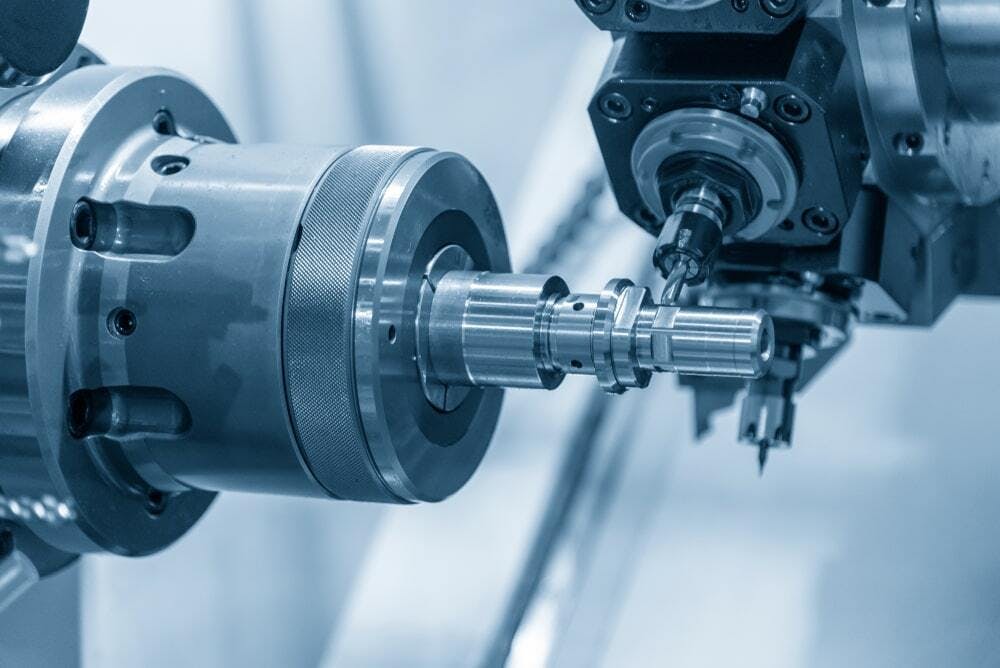

Introduction to CNC Lathes

In modern manufacturing, CNC lathes are essential for producing precision parts efficiently. CNC, or Computer Numerical Control, automates machining tools, allowing manufacturers to create complex shapes with ease. Industries such as automotive (e.g., engine components), aerospace (e.g., landing gear components), and medical (e.g., surgical instruments) rely on CNC lathes for high-quality production. If you’re in the market for a CNC lathe for sale, investing in these machines can significantly enhance your operational efficiency and meet the high standards required in today’s competitive landscape.

Benefits of Buying a CNC Lathe

Cost Efficiency

When considering a CNC lathe for sale, one of the primary factors is cost. Purchasing used CNC lathes can save manufacturers up to 50% on initial investment compared to new models while still providing excellent performance. Many manufacturers find that used machines can offer the same capabilities as new ones at a fraction of the cost. This approach not only saves money but also allows businesses to allocate resources to other critical areas.

However, if you prefer to invest in new machinery, HIRUNG offers high-quality CNC lathes that are competitively priced. Our machines not only provide exceptional performance but also come with a guarantee of quality that ensures long-term reliability and efficiency.

Operational Efficiency

CNC lathes are designed to enhance productivity. With automated operations, they can run continuously, reducing labor costs and minimizing human error. This efficiency translates into shorter production times—often reducing machining time by 30% or more—and higher output rates, making them an invaluable asset for any manufacturing facility.

Key Factors to Consider When Buying a CNC Lathe

Types of CNC Lathes

Understanding the different types of CNC lathes available is crucial when making a purchase. Here are some common models:

- Swiss-style Lathes: Designed for high accuracy, Swiss-style lathes are ideal for producing small, precise parts. They are commonly used in industries that require tight tolerances.

- 2-Axis Lathes: Perfect for simpler tasks, 2-axis lathes are suitable for basic turning operations. They are often used in smaller workshops or for less complex components.

- 3-Axis Lathes: Offering more versatility for complex shapes, 3-axis lathes allow for additional movements, making them suitable for more intricate machining tasks.

- Multitasking Lathes: These advanced machines combine turning and milling capabilities, providing enhanced functionality and enabling manufacturers to perform multiple operations in a single setup.

Specifications

When evaluating a CNC lathe, pay attention to key specifications that can impact your production capabilities:

- RPM (Revolutions Per Minute): Higher RPMs allow for faster machining, which can significantly increase productivity. Look for lathes with adjustable RPM settings to accommodate various materials and part designs.

- Chuck Size: This determines the maximum diameter of the workpiece that can be handled. Ensure the chuck size aligns with the types of projects you plan to undertake.

- Maximum Turning Diameter: Understanding this specification is essential for determining the size of parts you can produce. A larger turning diameter expands your machining capabilities, allowing you to work on bigger components.

Glossary of Terms

- RPM: The number of revolutions a spindle makes in one minute; higher RPMs generally lead to faster machining.

- Chuck Size: The size of the clamping device that holds the workpiece; it affects what sizes of materials can be machined.

Maintenance and After-Sales Support

One crucial aspect often overlooked is after-sales support. A reliable manufacturer will provide comprehensive maintenance services and support to ensure your CNC lathe operates smoothly over its lifespan. At HIRUNG, we pride ourselves on our exceptional after-sales service. Since our international sales began in 2015, we have exported over 1,000 machine tools with fewer than 20 failure notifications per year. This track record speaks volumes about the stability and reliability of our machines.

Our founder, Mr. Rocky Wu, guarantees that if any issues arise with your HIRUNG machine tools, we will provide the fastest solutions available. You won’t need to station maintenance engineers at your facility around the clock; our machines are designed to minimize breakdowns and maximize productivity.

Frequently Asked Questions (FAQs)

What is the average lifespan of a CNC lathe?

The average lifespan of a CNC lathe can range from 10 to 20 years, depending on usage and maintenance. Regular upkeep can significantly extend this lifespan.

How do I choose the right CNC lathe for my business?

Consider your production needs, budget, and space constraints. Evaluate different models based on their specifications and features to find the best fit.

What maintenance is required for CNC lathes?

Regular maintenance includes lubrication, cleaning, checking alignment, and replacing worn parts as necessary. Following manufacturer guidelines will ensure optimal performance.

Conclusion

Investing in a CNC lathe for sale can transform your manufacturing capabilities by enhancing efficiency and precision while reducing costs. By understanding the benefits and key features of CNC lathes, you can make an informed decision that aligns with your business goals.

If you’re new to CNC lathes and would like more information or resources, we offer free consultations tailored to your needs. For experienced buyers looking for high-quality machinery, feel free to request a quote or schedule a demo with us at HIRUNG! Our commitment to providing stable machine tools and excellent after-sales service will ensure you have all the support you need for your manufacturing journey.

Learn More About CNC Lathes:

Which CNC Machine Should You Choose: 3-Axis, 4-Axis, or 5-Axis?